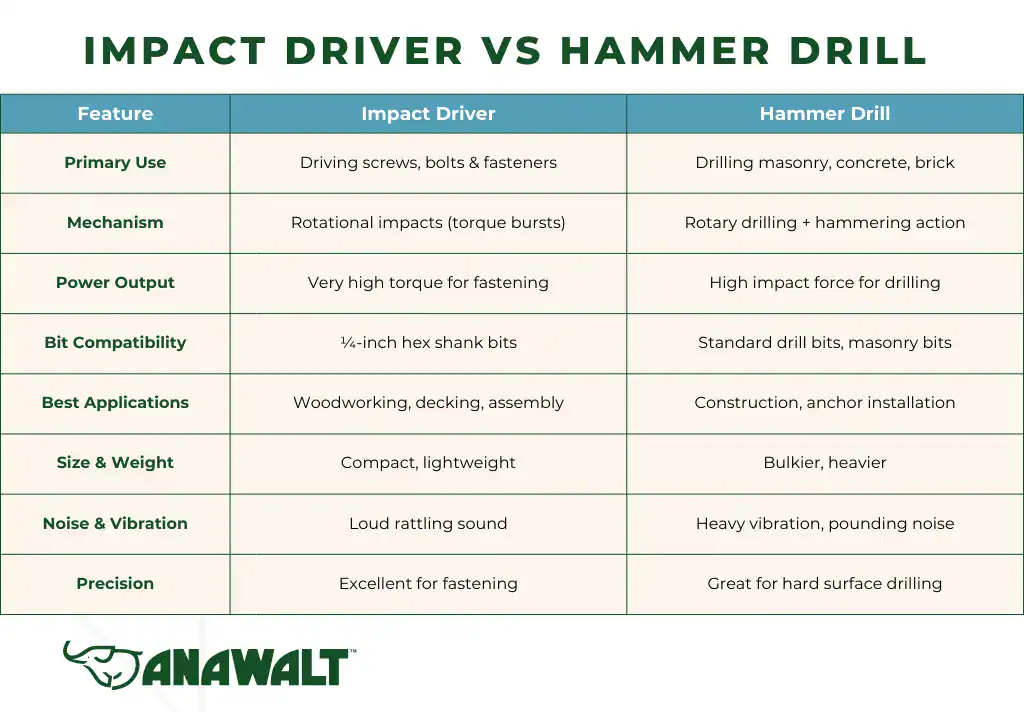

An impact driver and a hammer drill look like close cousins. Both are compact, equipped with a pistol grip, and have rotating chucks. Both are loud enough to wake the neighbors. But they couldn’t be more different.

One specializes in brute-force persuasion — like the bouncer who never asks politely — while the other is more of a finesse player.

Confusing them is more than a rookie mistake; it’s a fast track to stripped screws, cracked masonry, and frustration.

Both tools pack serious power, but they’re designed for different jobs.

What Is an Impact Driver?

Unlike a standard drill, an impact driver delivers rotational force through rapid bursts of impact torque. This unique mechanism prevents cam-out — that frustrating moment when your screwdriver slips out of the screw head and strips it.

The tool excels in woodworking projects, deck building, furniture assembly, and automotive work. A ¼-inch hex shank system locks bits in place.

An impact driver is designed to drive screws and bolts with high torque using concussive rotational force.

What Is a Hammer Drill?

A hammer drill combines standard rotary drilling with a percussive hammering action, creating a miniature jackhammer effect. This dual-action mechanism chips away at hard materials while the bit spins, making it the preferred choice for drilling into concrete, brick, and masonry.

Most hammer drills offer versatility by switching between standard and hammer drill modes. This flexibility makes them valuable for both regular drilling tasks and heavy-duty masonry work.

A hammer drill combines rotation with a hammering action to bore into hard materials like concrete, brick, and stone.

Purpose & Primary Applications

Impact Driver Applications

Impact drivers shine when you need high torque for fastening tasks:

- Installing deck screws into treated lumber

- Driving lag bolts through thick materials

- Assembling furniture with long screws

- Automotive repairs with stubborn bolts

- Cabinet installation with multiple fasteners

Hammer Drill Applications

Hammer drills tackle the tough drilling jobs that standard drills can’t handle:

- Creating anchor points in concrete foundations

- Drilling through brick walls for mounting brackets

- Installing conduits in masonry walls

- Setting fence posts in concrete footings

- Boring holes for plumbing through stone

A homeowner uses a hammer drill to bore into concrete.

How Each Tool Works

Impact Driver Mechanism

An impact driver’s hammer and anvil system generate rotational impacts. The tool automatically delivers more power when resistance increases — up to 4,000 impacts per minute. This action prevents the motor from stalling and reduces strain on your wrist.

Hammer Drill Mechanism

A hammer drill’s cam-driven system creates forward percussion while the chuck rotates. This produces thousands of tiny hammering actions — sometimes up to 48,000 beats per minute — while spinning to chip away hard materials.

Power & Torque Comparison

Impact drivers typically generate 1,500 to 4,000 inch-pound torque, with some professional models reaching even higher. This massive torque output makes driving long screws effortless, even through dense materials.

Hammer drills prioritize impact energy over torque, typically measuring their percussive force in joules. Most consumer models deliver 2–5 joules of impact energy, while heavy-duty versions can exceed 15 joules for demanding masonry work.

A woman uses an impact driver to plant a screw in a heavy board.

Bit Compatibility & Versatility

Impact Driver Bits

Impact drivers use ¼-inch hex shank bits that automatically lock into the chuck. These can handle the tool’s high-torque impacts without breaking, and include:

- Phillips and flathead screwdriver bits

- Hex bits for Allen screws

- Torx bits for specialty fasteners

- Socket adapters for nuts and bolts

Hammer Drill Bits

Hammer drills accommodate standard round shank drill bits, plus specialized masonry bits for percussion drilling. The chuck system varies by model:

- Keyed chucks require a chuck key for tightening

- Keyless chucks tighten by hand

- SDS chucks (on professional models) provide superior bit retention for heavy-duty work

A hammer drill can function as a small jackhammer to break up concrete, bricks, and masonry.

Size, Weight & Handling

Impact drivers maintain a compact, lightweight design, typically weighing 2–4 pounds.

Their shorter length makes them ideal for tight spaces, overhead work, and extended use without fatigue. The tool’s center of gravity sits close to your grip, improving control and reducing wrist strain.

Hammer drills are inherently bulkier and heavier, usually weighing 4-8 pounds or more.

Additional weight comes from the percussion mechanism and the sturdier construction needed to handle masonry work. This mass provides stability and reduces bounce when drilling into hard materials.

Noise and Vibration Levels

Both tools generate significant noise, but in different ways. Impact drivers produce a distinctive loud “rattling” or “chattering” sound during operation, especially under load. The sharp but intermittent noise occurs only when the impact mechanism engages.

Hammer drills create heavy vibrations transmitted through the tool body, with a continuous pounding sound in hammer mode. This vibration can be tiring during extended use, making anti-vibration features important for comfort and control.

When You Need Both Tools

Here are common scenarios where each tool plays a specific role:

- Building a Deck: Use the hammer drill to create pilot holes in concrete for ledger board installation, then switch to the impact driver for driving deck screws and lag bolts through lumber.

- Installing Wall-Mounted Cabinets: The hammer drill bores holes in masonry walls for anchors, while the impact driver secures screws into those anchors and drives fasteners into wall studs.

- Basement Framing: Use the hammer drill to drill anchor holes in concrete flooring, then the impact driver to fasten the bottom plates and assemble the wood frame.

FAQs: Impact Drivers vs. Hammer Drills

Q: Can I use an impact driver to drill holes?

While possible with the right bits, impact drivers aren’t meant for precision drilling. The impacting action can cause bits to walk or create oversized holes. Save drilling tasks for your regular drill or hammer drill.

Q: Will a hammer drill work for driving screws?

Hammer drills can drive screws when switched to drill-only mode, but they lack the controlled torque of an impact driver. You’re more likely to overdrive screws or strip heads.

Q: Which tool should I buy first as a beginner?

Start with an impact driver for most DIY projects. It handles most fastening tasks around the house and costs less than a quality hammer drill.

Q: Do I need special bits for each tool?

Yes. Impact drivers require hex shank bits designed to handle high torque, while hammer drills work with standard drill bits plus specialized masonry bits for concrete work.

Q: How do I know when to use hammer drill mode?

Switch to hammer mode when drilling into concrete, brick, stone, or masonry block. Use regular drill mode for wood, metal, or plastic materials.

Q: Can these tools replace my regular drill?

An impact driver can handle most screw-driving tasks better than a regular drill, but you’ll still want a standard drill for precision hole-making and delicate materials.

Q: What’s the typical battery life for cordless versions?

Battery life varies by brand and usage, but expect 2–4 hours of moderate use. Impact drivers typically run longer than hammer drills.

Q: Are brushless motors worth the extra cost?

Brushless motors provide longer runtime, more power, and extended tool life. If you use these tools frequently, the investment pays off in performance and durability.