If you drill, saw, or glue, chances are you’ll need a clamp to hold things steady.

The simple iron clamping devices of medieval forges have morphed into more than 50 specialized types, each engineered for different purposes.

The humble C-clamp traces its roots to blacksmithing workshops, where craftsmen needed steady hands and reliable pressure.

Ancient Romans and Greeks laid the groundwork with wooden wedges and primitive vises, but adjustable screw-driven clamps were uncommon until the Industrial Revolution.

Some modern clamps can apply over 2,000 pounds of pressure — enough to crush softer metals if you’re not careful. Each type serves a different purpose, from spring clamps for quick fixes to massive bar clamps spanning several feet.

In this blog, we’ll cover 12 of the most popular clamps in the home and workshop and briefly describe their uses.

12 Common Types of Clamps

1. C-Clamps (or G-Clamps)

C-clamps, named for their C-shaped frame, have a threaded screw to apply pressure between a small anvil and the screw’s jaw.

Best For

- General-purpose clamping: Holding wood, metal, or plastic.

- Secure holds: Keeping small workpieces steady while you drill, cut, or sand.

- Welding projects: Steel C-clamps can withstand the heat of welding.

- Temporary vise: A C-clamp can act as a simple bench vise in a pinch.

C-Clamp – A C-shaped clamp with a screw mechanism, ideal for holding materials tightly in place. This “C” is backwards because we’re still learning the alphabet.

2. Bar Clamps (or F-Clamps)

Bar clamps, also known as F-clamps due to their shape, consist of a long bar with a fixed jaw and a sliding jaw. They offer a longer reach than C-clamps and are a staple in woodworking.

Best for:

- Edge-gluing: Perfect for joining boards together to create tabletops or panels.

- Large workpieces: The long bar provides reach across wider pieces of material.

- Cabinetmaking: Ideal for holding cabinet components together during assembly.

Bar Clamps – Long clamps with a sliding jaw on a metal bar, great for woodworking and wide surfaces.

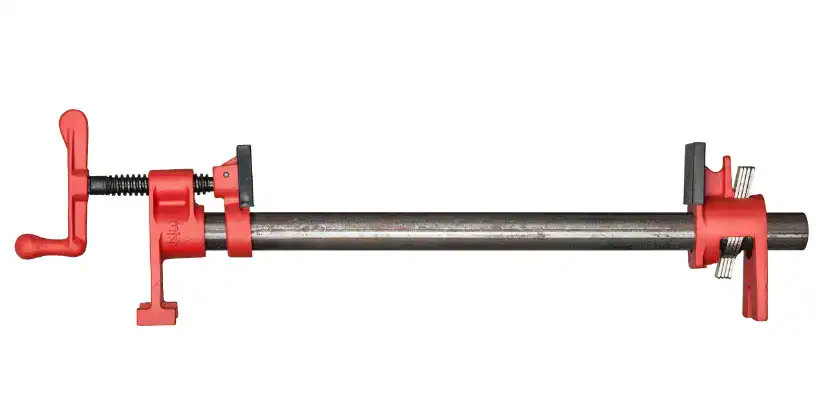

3. Pipe Clamps

Pipe clamps are heavy-duty tools that offer incredible flexibility. The clamp fixtures are mounted on a threaded pipe length, meaning you can make the clamp as long as you need, just by swapping out the pipe.

Best for:

- Large glue-ups: The go-to choice for building doors, large panels, and tabletops.

- Heavy-duty pressure: Delivers strong, even pressure required for robust woodworking projects.

- Cabinet assembly: Keeps large cabinet boxes square and secure during glue-up.

Pipe Clamps – Adjustable clamps that use sections of pipe to span large distances for heavy-duty clamping.

4. Spring Clamps

Think of spring clamps as strong, oversized clothespins. They’re easy to use with one hand, making them perfect for light-duty tasks.

Best for:

- Quick holds: Ideal for temporarily securing small joints or craft pieces while the glue sets.

- Lightweight materials: Works well for clamping thin wood, fabric, or plastic sheeting.

- An extra hand: Use them to hold a guide in place or keep a tarp out of the way.

Spring Clamps – Small, lightweight clamps with spring tension, perfect for quick, temporary holds.

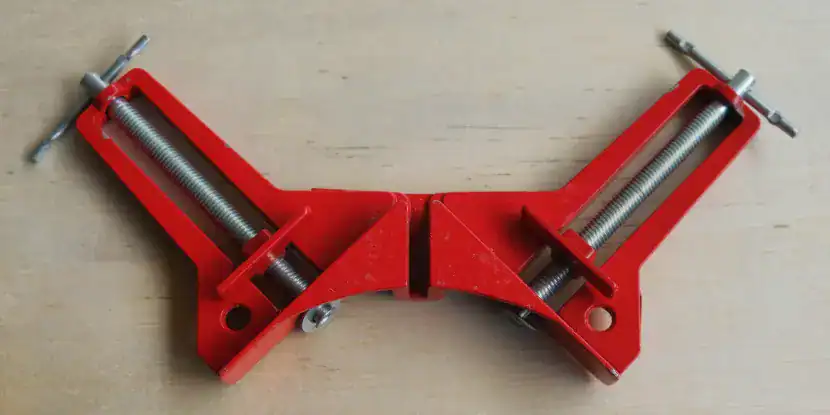

5. Corner Clamps

As the name suggests, corner clamps are designed to create perfect 90-degree joints. They hold two pieces of material at a right angle to construct frames, boxes, and drawers.

Best for:

- Joining wood at 90°: Essential for picture frames, cabinets, and boxes.

- Ensuring square corners: Keeps joints perfectly aligned while you glue, nail, or screw them together.

- Small furniture assembly: A huge help when assembling drawers or small shelves.

Corner Clamps – Designed to hold two pieces at a right angle, commonly used in frame and cabinet assembly.

6. Parallel Jaw Clamps

A parallel jaw clamp has a steel bar with two jaws that remain perfectly parallel during tightening. One jaw slides, the other is fixed; pressure is applied with a large screw handle.

Best For

- Even parallel pressure: Excellent for glue-ups of panels, tabletops, or cabinets.

- Large capacity: Available in long lengths, perfect for big assemblies.

- High clamping Force: Can exert a lot of pressure without bowing the workpiece.

- Precision clamping: Use them when perfect alignment is critical.

Parallel Jaw Clamps – Clamps with wide jaws that stay parallel under pressure, providing even, square clamping across large surfaces.

7. Hand-Screw Clamps

A hand-screw clamp has hardwood jaws and dual steel-threaded screws with handles. The jaws can be angled independently, and the hardwood jaws are kinder to softer surfaces than steel.

Best For

- Adjustable angles: Can clamp irregular or angled shapes that straight clamps can’t grip.

- Gentle grip: Wood jaws distribute pressure, reducing dents in delicate woods.

- Versatility: Works for both small, delicate items and oddly shaped workpieces.

Hand-Screw Clamps – Adjustable wooden-jawed clamps that apply strong, even pressure at multiple angles.

8. Bench Vises

A bench vise is a permanent fixture bolted directly to your workbench. It provides a powerful and stable grip for heavy-duty tasks requiring force.

Best For

- Heavy-duty work: The ultimate tool for sawing, chiseling, planing, or filing.

- Metalworking: Securely holds metal for drilling, grinding, and cutting.

- Repeated tasks: A reliable station for any work that requires a solid, unmoving hold.

Bench Vises – Heavy-duty clamps permanently mounted to a workbench for securing workpieces during cutting or drilling.

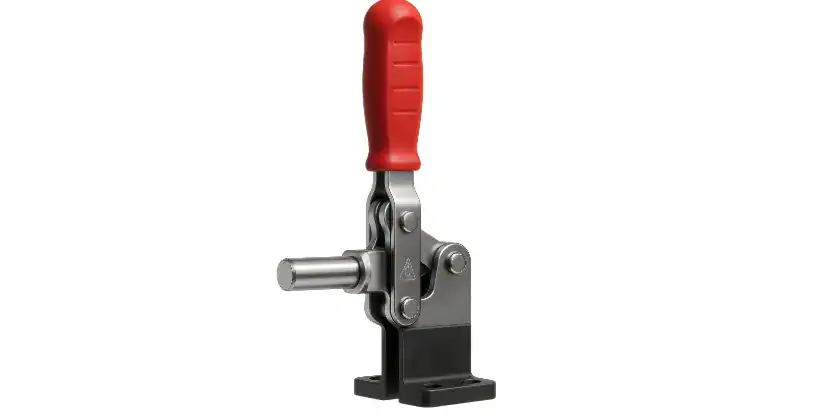

9. Toggle Clamps

Toggle clamps operate with a quick-action lever that locks the clamp, making them perfect for production work or custom jigs where you need to secure and release a workpiece quickly.

Best for

- Jigs and fixtures: Commonly used on router tables, drill presses, and saw sleds.

- Repetitive clamping: Ideal for production runs where speed is essential.

- Welding jigs: Quickly secure metal parts for welding or fabrication.

Toggle Clamps – Quick-action clamps with a lever and pivot system for fast, secure holding.

10. Strap Clamps

A strap clamp is your best bet when you need to secure something round, rectangular, or just plain weird. It uses a flexible nylon strap that tightens around the object, applying gentle, even pressure.

Best for

- Irregular shapes: Perfect for clamping chair legs, barrels, or circular frames.

- Picture frames: Holds all four corners together for glue-up.

- Gentle clamping: Avoids marring delicate or finished surfaces.

Strap Clamps – Flexible clamps that use a tensioned strap to secure irregular or rounded shapes.

11. Quick-Grip (or One-Hand) Clamps

A pistol-grip handle allows you to tighten the clamp with one hand, leaving your other hand free to position the workpiece. Many models can be converted to act as a spreader.

Best for

- One-handed operation: Essential when you need to hold your project and clamp simultaneously.

- Fast clamping: Great for quick, temporary holds during assembly.

- Spreading: Can also push pieces apart instead of pulling them together.

One-Hand Clamps – Lightweight clamps that can be tightened or released with a single hand for convenience.

12. Specialty Clamps

Dozens of specialty clamps are designed for very specific jobs. Here are a few you might encounter:

- Edge Clamp: Secures edge banding or laminates to plywood or particleboard.

- Sash Clamp: An extra-long bar clamp used for large-scale projects like doors.

- Track Clamp: Slides into the tracks of saw guides and jigs.

- Magnetic Clamp: Used in welding to hold metal pieces at specific angles.

- Flooring Clamp: Pulls tongue-and-groove flooring boards tightly together.

Sash Clamp – A long, heavy-duty woodworking clamp used to hold large panels, doors, or frames securely in place.

FAQs: Types of Clamps

Q: What are the best clamps for beginners?

A good starting set includes a few C-clamps for general use, a pair of quick-grip clamps for one-handed convenience, and a couple of medium-sized bar clamps for woodworking projects.

Q: Can I use a C-clamp for woodworking?

Yes, C-clamps are very useful in woodworking. However, their metal jaws can mar the surface of the wood, so it’s a good practice to use wood scraps or pads between the clamp and your workpiece to protect it.

Q: What’s the difference between a bar clamp and a pipe clamp?

A bar clamp has a fixed length, while a pipe clamp’s length is determined by the pipe it’s attached to. Pipe clamps generally offer stronger clamping pressure and are better for very large glue-ups.

Q: How do I prevent my clamps from damaging my project?

Use clamp pads or small pieces of scrap wood between the clamp jaws and your workpiece. This distributes the pressure more evenly and prevents dents or marks, especially on softer woods.

Q: Are more expensive clamps better?

Often, yes. Higher-priced clamps from reputable brands tend to be more durable, apply pressure more evenly, and have smoother mechanisms. For fine woodworking, investing in quality parallel or bar clamps is worth it.

Q: What is a “spreader” function on a clamp?

Some one-handed bar clamps have a reversible jaw. By moving the jaw to the opposite end of the bar, the clamp can push outward instead of pulling inward. This is useful for disassembling furniture or bracing projects from the inside.

Q: How many clamps do I need to glue a tabletop?

A good rule of thumb is to place one clamp every 8–12 inches along the length of the boards. You should also alternate clamps on the top and bottom of the panel to ensure even pressure and prevent the panel from bowing.

Q: Can I use spring clamps for gluing?

Spring clamps are best for temporarily holding small, lightweight pieces in place while the glue sets. A bar clamp or C-clamp is a much better choice for larger joints that require significant pressure to close gaps.