Have you ever tightened a nut with pliers? It sort of works until the nut strips. Reach for a wrench instead.

The modern wrench emerged in the 1800s, alongside the rise of machine manufacturing and standardized hardware. Before that, blacksmiths and craftsmen often made custom spanners or keys for specific machinery.

A Brief History of the Wrench

- In the 15th–16th centuries, “spanners” were custom-built to fit specific fasteners.

- 1835: The first patent for a screw wrench (an early adjustable wrench) was granted to Solymon Merrick in the US.

- 1840s–1860s: Improvements in adjustable designs spread; English engineer Richard Clyburn (1842) developed an early adjustable spanner that influenced later tools.

- 1869 (US): Charles Moncky created a more modern adjustable wrench, later called the monkey wrench.

- 1891 (Sweden): Johan Petter Johansson patented the adjustable spanner that closely resembles what we use today (often called the Crescent wrench after the Crescent Tool Company).

- Over time, the wrench became standard in industries from automotive repair to aerospace, and is now manufactured in countless variations.

Wrench vs. Pliers: What’s the Difference?

- Pliers grip, hold, and bend objects. While some types can turn a nut in a pinch, their serrated jaws can easily strip and damage the fastener.

- Wrenches fit snugly around nuts and bolts, providing maximum torque without slipping.

A wrench is always better if you need to turn a nut or bolt.

Common Types of Wrenches & Their Uses

1. Open-End Wrench

Has U-shaped openings on one or both ends. Each end is a different size to fit two different-sized fasteners.

- Best Uses: Working in tight spaces where you can’t fit a socket over the fastener, like behind an appliance. The open design lets you slip it onto a nut or bolt from the side.

- Distinguishing Features: The open-ended jaws are usually angled at 15 degrees to the handle to allow for a wider range of movement in confined areas.

Open-End Wrench – A double-ended tool with U-shaped jaws for gripping nuts and bolts.

2. Box-End Wrench

Features a closed loop at each end, designed to enclose a fastener. Like the open-end wrench, it usually has a different size on each end.

- Best Uses: Loosening stubborn bolts. The closed design provides excellent grip and reduces the risk of slipping and stripping the fastener head.

- Distinguishing Features: The closed, continuous loop grips all six points (or twelve) of a hexagonal nut, distributing force evenly.

Box-End Wrench – A closed-loop wrench that fits snugly over hexagonal or square fasteners.

3. Combination Wrench

The most common wrench for home repairs has an open-end jaw on one side and a box-end loop on the other, both of the same size.

- Best Uses: With the box end, you can break a tight nut loose and switch to the open end to unscrew it quickly.

- Distinguishing Features: One open end and one box end of the same size on a single handle.

Combination Wrench – A dual-purpose tool with an open-end on one side and a box-end on the other.

4. Adjustable Wrench (Crescent Wrench)

Also known by the brand name Crescent, it has one fixed jaw and one adjustable jaw, controlled by a screw mechanism in the handle.

- Best Uses: It adapts to various nut and bolt sizes, saving you from carrying a complete set of fixed wrenches for simple repairs.

- Distinguishing Features: The movable jaw makes it a one-size-fits-all tool, though it provides a less secure grip than a fixed-size wrench.

Adjustable Wrench – A versatile wrench with a movable jaw to fit various fasteners.

5. Allen Wrench (Hex Key)

An L-shaped tool with a hexagonal tip.

- Best Uses: Tightening and loosening screws and bolts with a hexagonal socket in the head. Often used in furniture assembly.

- Distinguishing Features: The long arm provides reach and leverage, while the short arm allows access in tight spots.

Allen Wrench – A small L-shaped tool for driving screws and bolts with hexagonal sockets.

6. Socket Wrench (Ratchet)

Contains a ratcheting mechanism and a series of detachable sockets of various sizes.

- Best Uses: The ratchet lets you continuously tighten or loosen a fastener without removing and repositioning the wrench.

- Distinguishing Features: The ratcheting handle and interchangeable sockets make it highly efficient for jobs with many fasteners, like building a deck.

Socket Wrench – A wrench with interchangeable sockets and a ratcheting handle for quick turns.

7. Torque Wrench

A specialized tool that applies precise torque (rotational force) to a fastener.

Best Uses: Essential for automotive work, especially on engine components, wheels, and suspension parts, where over- or under-tightening can cause severe damage.

Distinguishing Features: A mechanism indicates when the preset torque is reached.

Torque Wrench – A precision tool that measures and applies a specific amount of torque to a fastener.

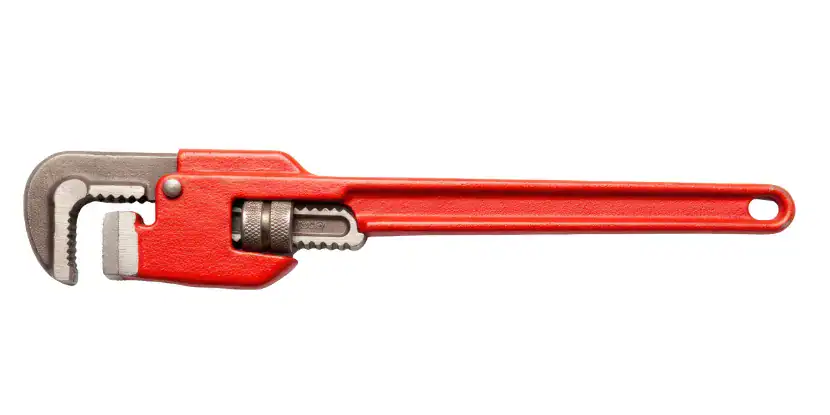

8. Pipe Wrench (Monkey Wrench)

A heavy-duty adjustable wrench with serrated jaws.

- Best Uses: Designed for gripping and turning soft iron pipes and round fittings, common in plumbing repairs. The teeth dig into the material for a non-slip grip.

- Distinguishing Features: Its key feature is self-tightening, serrated jaws. However, the teeth will damage hexagonal nuts.

Pipe Wrench – A heavy-duty wrench with serrated jaws for gripping and turning pipes.

9. Chain Wrench

Incorporates a chain length to grip large, round, or irregularly shaped objects.

- Best Uses: Working on large-diameter pipes or components that a standard pipe wrench can’t handle, like oil filters on large engines.

- Distinguishing Features: Instead of jaws, it has a loop of heavy-duty chain that tightens as you turn the handle.

Chain Wrench – A wrench that uses a chain loop to grip irregular or round objects like pipes.

10. Crowfoot Wrench

An open-end wrench head without a handle, designed to be attached to a ratchet handle or extension.

- Best Uses: Reaching fasteners in extremely tight or awkward locations where a standard wrench or socket won’t fit, such as in automotive engine bays or behind a water heater.

- Distinguishing Features: Its handle-less design makes it a unique attachment for a socket wrench set.

Crowfoot Wrench – An open-end wrench head that attaches to a ratchet handle for hard-to-reach spots.

11. Strap Wrench

Like a chain wrench, only with a fabric or rubber strap to grip objects without scratching them.

- Best Uses: Plumbing work on polished or plastic pipes, or removing stuck jar lids and oil filters without causing damage.

- Distinguishing Features: The soft, non-marring strap grips delicate surfaces.

Strap Wrench – A wrench with a flexible strap for gripping smooth, round surfaces without damage.

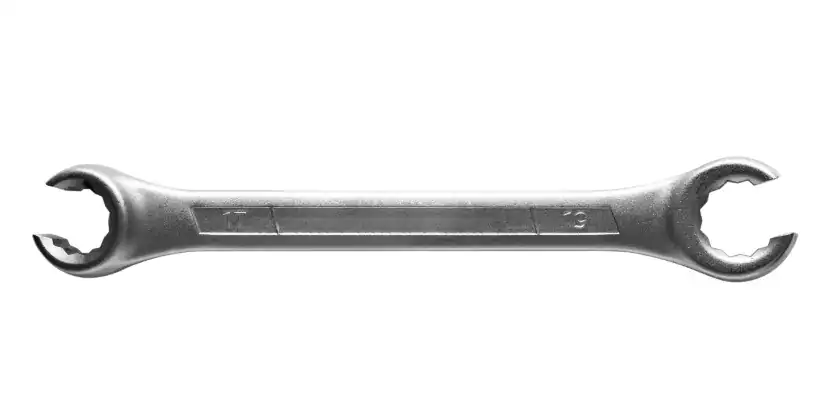

12. Flare Nut Wrench

Similar to a box-end wrench, but with a small section removed from the loop.

- Best Uses: Gripping soft metal fittings in brake lines, fuel lines, and some appliance connections. It provides a firmer grip than pliers and can reach into tight spaces.

- Distinguishing Features: The small cutout in the loop allows for slipping over fittings without completely disconnecting them.

Flare-Nut Wrench – A wrench with an open-ended, partial ring for gripping soft metal fittings like brake lines.

13. Ratchet Box Wrench

Combines the slim profile of a combination wrench with the speed of a ratchet.

- Best Uses: Working in tight engine compartments or behind appliances where you don’t have room for a traditional ratchet handle.

- Distinguishing Features: The box-end has a built-in ratcheting mechanism, allowing fast work without repositioning the wrench.

Ratchet Box Wrench – A box-end wrench with a built-in ratcheting mechanism for faster turning.

14. Pliers Wrench

A hybrid tool with smooth, parallel jaws that can be adjusted with the push of a button.

- Best Uses: It acts like a set of adjustable wrenches and pliers in one, providing a powerful, non-slip grip without damaging fasteners. It’s great for holding, pressing, and bending applications.

- Distinguishing Features: The parallel-closing jaws provide full contact on nuts, preventing rounding.

Pliers Wrench – A hybrid tool combining pliers’ gripping action with a smooth wrench-like jaw.

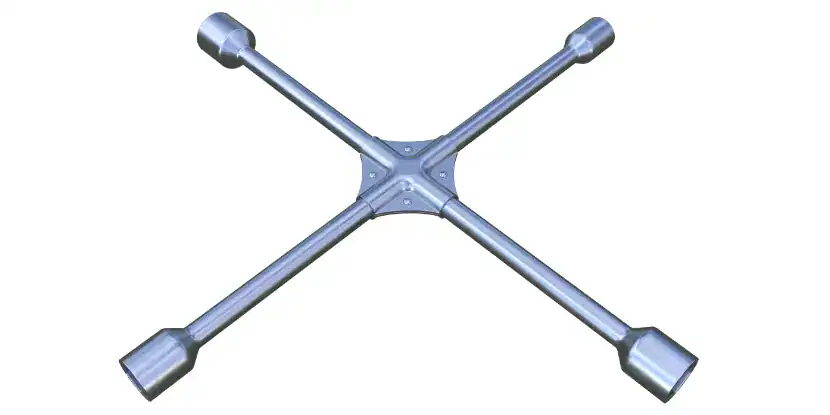

15. Lug WrenchA heavy-duty wrench designed for loosening and tightening lug nuts on vehicle wheels.

- Best Uses: Emergency tire changes or routine wheel maintenance. It’s also useful for large, stubborn bolts and fasteners.

- Distinguishing Features: The long handle provides extra leverage to loosen tight lug nuts easily. Some models come with different-sized sockets.

Lug Wrench – A cross- or L-shaped wrench used to remove and tighten vehicle lug nuts.

16. Basin Wrench

A specialized tool used to reach and tighten faucet mounting nuts under sinks.

- Best Uses: Any plumbing project that requires reaching into tight spaces, such as installing new faucets or repairing leaky ones.

- Distinguishing Features: A long, narrow handle with a pivoting jaw.

Basin Wrench – A T-handled wrench with a pivoting jaw, designed for tightening faucet fittings in tight spaces.

FAQs: Types of Wrenches

Q: Can I use an adjustable wrench for everything?

It’s tempting, but an adjustable wench offers a less secure grip than a fixed-size box-end or combination wrench. A fixed wrench is always better for high-torque applications or to prevent stripping a bolt.

Q: What’s the difference between a pipe wrench and a standard wrench?

A pipe wrench has serrated jaws designed to grip round, soft metal pipes and will damage hexagonal nuts. A standard wrench has smooth jaws to fit precisely on nuts and bolts without damaging them, which you’ll need for most DIY tasks.

Q: Why do some wrenches have 6 points and others have 12?

A 6-point wrench offers better grip and is less likely to strip a fastener, making it ideal for high-torque situations. A 12-point wrench is more convenient because it can engage a fastener at more angles, making it easier to use in tight spaces where movement is limited.

Q: What is a “cheater bar,” and should I use one?

A “cheater bar” is a pipe or other extension slipped over a wrench handle to increase leverage. While it makes turning a fastener easier, it’s generally not recommended as it can exceed the tool’s design limits, leading to a broken wrench or a stripped bolt. Using a longer wrench or a breaker bar is a safer alternative.

Q: How do I maintain my wrenches?

Keep your wrenches clean and dry to prevent rust. Wipe them down after use, especially if they’ve been exposed to moisture or corrosive materials. Store them in a toolbox or on a wrench rack to keep them organized and protected.

Q: What does SAE and Metric mean for wrenches?

SAE (Society of Automotive Engineers) wrenches are measured in inches and fractions of an inch, commonly used on vehicles and machinery made in the United States. Metric wrenches are measured in millimeters and are used on most foreign-made cars, appliances, and equipment.

Q: Is a torque wrench necessary for a DIYer?

A torque wrench isn’t necessary for most general household tasks. However, if you plan on doing any automotive work, especially on critical components like engine bolts or lug nuts, it ensures safety and prevents damage.

Q: What are the most essential wrenches for a beginner’s toolkit?

A good starter set includes a quality combination wrench set (both Metric and SAE), a medium-sized adjustable wrench, and a basic socket set with a ratchet handle. This collection will cover the majority of tasks around the home and garage.